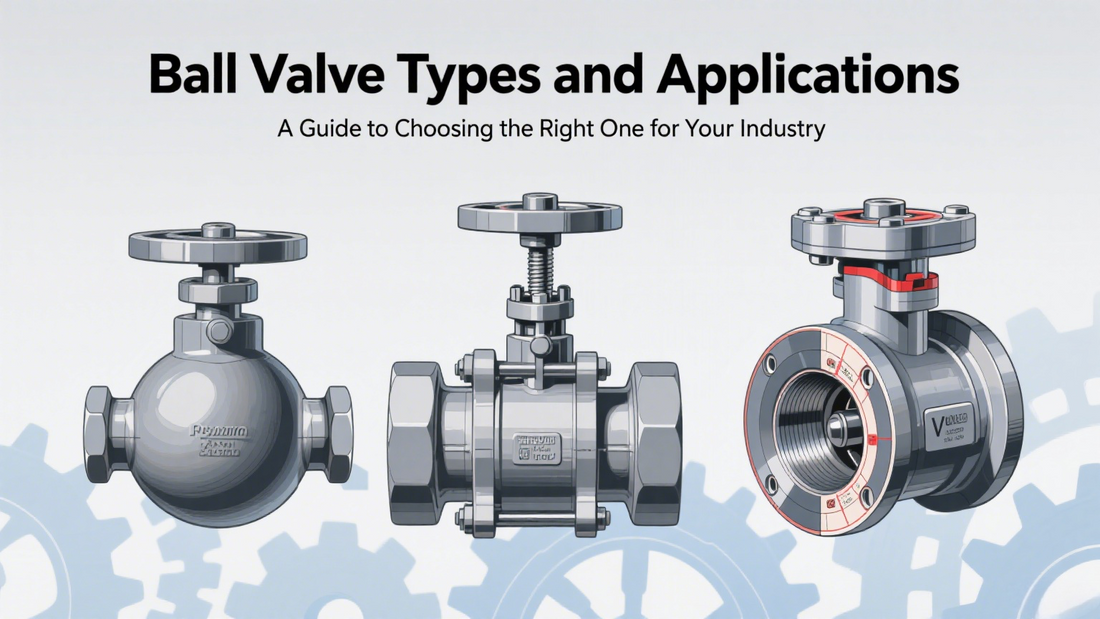

Ball Valve Types and Applications: A Guide to Choosing the Right One for Your Industry

Ball valves are among the most versatile valve types in industrial and commercial systems. Their straightforward design, dependable sealing, and ability to shut off flow quickly make them a go-to choice across countless applications—from everyday water pipelines to high-pressure oil and gas operations.

In this guide, we’ll break down the main types of ball valves, their material options, typical industry uses, and key considerations for selecting the right one for your specific needs.

What Is a Ball Valve and How Does It Work?

A ball valve is a quarter-turn valve that regulates fluid flow using a rotating ball with a central hole (known as a bore). When the bore aligns with the pipeline, the valve is fully open, allowing flow to pass through. A 90-degree turn rotates the ball to block the pipeline, shutting off flow completely.

Its key benefits include:

- Fast shut-off with minimal force required

- Tight sealing to prevent leakage

- Durability in high-pressure and high-temperature environments

- Low need for ongoing maintenance

Main Types of Ball Valves

1. Floating Ball Valve

The ball is held in place by two seats but has slight movement within the valve body. Sealing happens when line pressure pushes the ball against the downstream seat.

Best for: Low to medium pressure systems like water distribution networks and HVAC systems.

Example product: JIVTO Stainless Steel Floating Ball Valve

2. Trunnion-Mounted Ball Valve

The ball is supported by trunnions (mechanical anchors) at the top and bottom, which reduces wear on the seats.

Best for: High-pressure, large-diameter pipelines—common in oil & gas, petrochemical, and high-pressure steam systems.

3. V-Port Ball Valve

The ball or seat features a “V” shape, enabling precise flow control. Unlike basic on/off valves, it’s often used for throttling (adjusting flow rates).

Best for: Chemical dosing, water treatment, and process control applications.

4. Multi-Port Ball Valve

Comes with three or more ports, making it easy to divert or mix flow. This design cuts down on the number of valves needed in complex piping setups.

Best for: Process systems that require frequent flow redirection.

5. Cavity Filler Ball Valve

A specialized seat design prevents fluid from getting trapped in the valve cavity. This boosts hygiene and avoids issues like freezing or contamination.

Best for: Food & beverage, pharmaceutical, and cryogenic services.

Materials and Seat Types

Valve Body Materials

- Stainless Steel: Offers excellent corrosion resistance, making it ideal for high-pressure and chemical handling applications.

- Example: JIVTO 2 PC Stainless Steel Ball Valve

- Brass: A cost-effective option, suitable for water, air, and non-corrosive fluids.

- PVC: Lightweight and corrosion-proof, perfect for low-pressure and chemical applications.

Seat and Seal Materials

- PTFE (Teflon): Works well for most general uses and resists many chemicals.

- PEEK: Stands up to high temperatures and pressures.

- Metal Seats: Handle abrasive media and extreme heat.

Common Industry Applications

- Water and Wastewater: Ball valves are used in pump systems, treatment plants, and distribution lines for reliable shut-off.

- Oil and Gas: High-pressure trunnion ball valves ensure safe operation in pipelines and refineries.

- Food and Beverage: Hygienic cavity-filler designs meet strict sanitary standards and prevent bacterial growth.

- Chemical Processing: Corrosion-resistant stainless steel bodies and PEEK seats safely handle aggressive chemicals.

- HVAC Systems: Floating ball valves provide efficient flow control for heating and cooling circuits.

How to Choose the Right Ball Valve for Your Industry

- Identify the Media Type: Consider whether you’re handling water, oil, gas, steam, slurry, or chemicals.

- Check Pressure and Temperature Ratings: Choose a valve that meets or exceeds your system’s requirements.

- Select Appropriate Materials: Match the valve body and seat material to the fluid’s corrosiveness and temperature.

- Pick the Right End Connection: Options include NPT, BSP, welded, or flanged connections—choose based on your piping setup.

- Factor in Maintenance Needs: For critical systems, opt for designs that make seat and seal replacement easy.

Conclusion

Selecting the right ball valve is key to ensuring your system runs efficiently, safely, and lasts long-term. By understanding the different types, materials, and applications, you can find a valve that fits your industry’s unique needs.

At JIVTO Store, we offer a wide range of stainless steel and brass ball valves built to perform in tough environments. Contact us today for a quote or to discuss a custom solution.