Comprehensive Guide to Understanding Valve Types

Valves, critical components in diverse industries, regulate liquid, gas, and slurry flow through pipelines and systems. This article explores several common valve types and their applications.

1. Gate Valves

Gate valves, linear motion valves utilizing a flat or wedge-shaped gate, are suitable for on/off operations and are frequently employed in water and wastewater systems. They provide a robust seal at full closure but lack flow regulation capabilities.

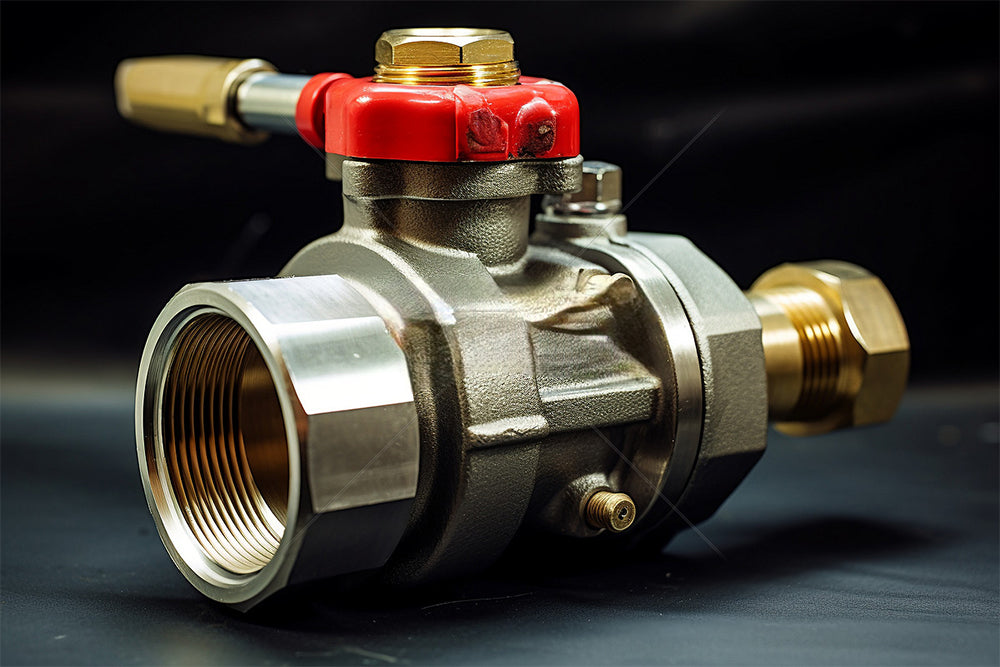

2. Ball Valves

Ball valves, featuring a spherical disc with a central hole, permit fluid passage when open. These valves offer swift operation and superior sealing, rendering them prevalent across industries.

3. Globe Valves

Globe valves, possessing a spherical body with an internal baffle, utilize a plug-type disc moving perpendicular to the flow path. They excel at flow regulation and are frequently utilized in precision control applications.

4. Butterfly Valves

Butterfly valves, comprising a disc rotating on a shaft, control flow swiftly. These valves, lightweight and compact, are typically employed in large-diameter pipes and low-pressure applications.

5. Check Valves

Check valves, designed to prevent backflow, allow flow in one direction, and close automatically upon flow reversal. Swing check, lift check, and ball check valves are among the various types available.

6. Diaphragm Valves

Diaphragm valves, employing a flexible diaphragm, are adept at handling corrosive or abrasive fluids. Their sanitary design makes them prevalent in the pharmaceutical and food processing industries.

7. Pinch Valves

Pinch valves, comprising a flexible tube "pinched" to halt the flow, are ideal for slurry and abrasive material handling as the valve mechanism stays dry.

8. Needle Valves

Needle valves, using a lengthy, tapered needle-like plunger, provide precise flow control. They are often employed in laboratory settings or for smaller flow applications.

Choosing the suitable valve for your application hinges on factors such as fluid type, pressure, temperature, and flow requirements. Recognizing each valve type's strengths and limitations is vital for optimal system performance and longevity.

In summary, valves are pivotal in fluid control across numerous industries. By selecting the appropriate valve type, you can ensure efficient operation, reduced maintenance, and extended equipment lifespan. If you have any questions, please feel free to contact me here